Mechanically stressed components such as terminal blocks and connectors require a good retention to the PC board. In order to obtain the same efficiency in production of SMT process (Surface Mount Technology) and mechanical

resistance typical of THT process (Through Hole Technology), these two technologies can be integrated in one process named THR (Through Hole Reflow).

PCB CHARACTERISTICS

1) Plated through holes;

2) Holes diameter: depends on pin dimension and on the accuracy of component deployment;

3) Soldering pad: depend on the pin dimension, paste quantity and stencil layout;

4) Volume of soldering paste can be calculated as follow.

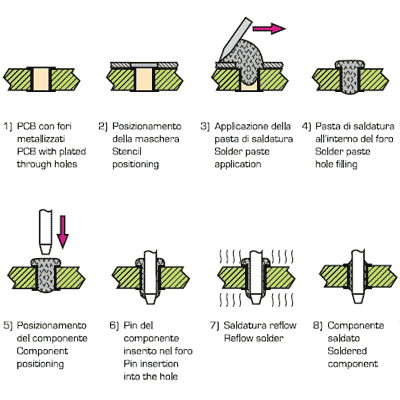

This process or method is also known as a PIP (Pin In Paste) and differently from SMT traditional components, the pins of connectors, terminal blocks and fuse-holders are inserted into PCB plated through holes previously filled with soldering paste and then soldered with Reflow technology as described on the following pictures.

PCB CHARACTERISTICS

1) Plated through holes;

2) Holes diameter: depends on pin dimension and on the accuracy of component deployment;

3) Soldering pad: depend on the pin dimension, paste quantity and stencil layout;

4) Volume of soldering paste can be calculated as follow:

Vh = Hole volume

Vn = Net volume

Vp = Soldering pin volume

S = PCB thickness

dh = PCB hole diameter

K = Evaporation factor (equal to 2 with paste estimated bleeding of 50%)