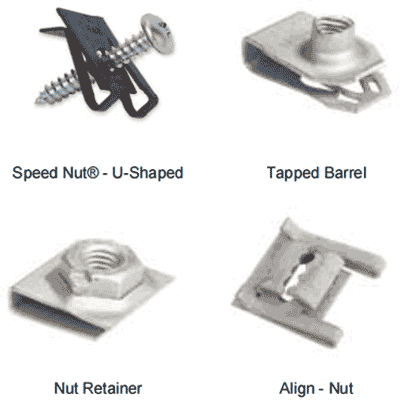

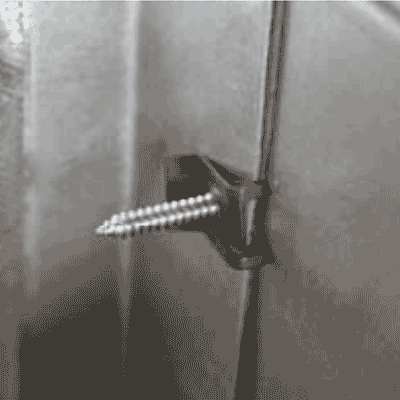

ARaymond Tinnerman U-nuts self-retain in screw-receiving

position to provide simple, rapid attachment of mating panels. They correct misalignment in panel mounting holes, do not turn as the screw is driven and will not freeze on screw threads.

Most U-nuts are single piece stampings available in single impression, 5-prong and threaded barrel styles. Nut retainers are two-piece assemblies that combine the strength of a cold-headed nut with the versatility of a sheet metal cage.

Multiple impression and floating cage align-nuts can be used in cases where there is excessive build variation.

Industries and Applications

• Universal – Can be used wherever a screw or bolt is used

• Used in place of clinch-nuts and weld-nuts

• Panel assembly applications in HVAC and white goods

Benefits

• Self-retain during assembly, improving assembly time and reducing costly welding and clinching costs

• Easy to assemble, requiring no special tools

• Serviceable – Parts disassemble easily and reliably

• Single-component design eliminates small parts handling and excessive part inventories

Performance Specifications

The strength of the joint greatly depends on the type of impression and screw size.

For course thread screws, single impression and 5-prong styles are a viable alternative. The strength of these parts correspond to the strength of the screw. They are easier to install, have lower profiles and make a cleaner joint.

For machine screws, threaded barrel parts are preferred. The tapped barrel strength equals that of the screw.

For larger sizes, nut retainers are recommended. These parts combine the strength of the nut with the flexibility of the spring steel cage.

Selection Criteria

First, select the thread specification required for the desired

joint strength. Next, select a fastener designed for the required panel thickness. Finally, select a nut that will accomodate the distance from the edge of the panel to the center line of the

mounting hole.

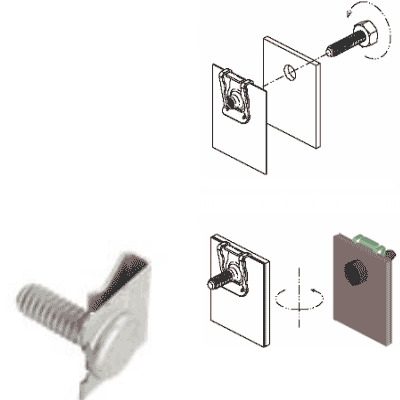

U-SHAPED BOLT RETAINERS

In some applications it may be advantageous to pre-assemble the bolt to the panel and drive a nut to secure the component. The component can “hang” from the bolt, allowing both hands to be free during the assembly operation.