In 2009, ARaymond and Tinnerman came together

ARaymond has always envisioned the future with a combination of imagination and realism. Its success can primarily be attributed to the long-term vision of its leaders and their ability to anticipate market trends by making crucial and early strategic decisions. Since 1865, ARaymond supported the glove, shoe, leather, textile, radio, construction, and automotive industries, each representing a decisive stage in the company’s progression. Today, the group holds 800 industrial patents. Always a prime mover, the innovative spirit inspired by Albert-Pierre Raymond has contributed to the independence of the group companies through five generations, and counting…

In 2009, ARaymond and Tinnerman came together to form one incredibly powerful fastener company.

TINNERMAN® AND SPEED NUT® HISTORY

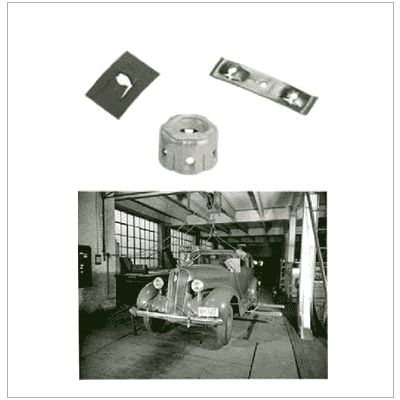

Tinnerman was founded in Cleveland, Ohio in 1870 by George Tinnerman and was known as the Tinnerman Stove Company, makers of high-end stoves. In 1936, Albert, George’s son, created a spring steel fastener known as the “Speed Nut®” in order to solve an ongoing issue with stove shipping. George Tinnerman, grandson of the founder, commercialized Speed Nuts® in markets beyond stoves – so successfully, in fact, that the stove business shutdown entirely. Tinnerman® became a trusted supplier of fasteners for WWII aircraft.

According to a 1947 Fortune Magazine article, the Tinnerman® Company used aggressive techniques to change the automobile industry. The time-saving fasteners held parts in place without the need for welding or riveting. At the time, an automobile manufacturer doubted that it was strong enough to hold fenders to bodies. A.H. Tinnerman responded by hoisting a 3,325 pound vehicle off the ground supported by a Speed Nut®. A.H. also created a plan to save Ford millions of dollars by changing the way automobiles were assembled – finding 400 unique places and applications for Tinnerman® products. It became an automotive revolution.

SPEED NUTS®

ARaymond Tinnerman Flat-Type Speed Nuts® are one- piece, self-locking, heat-treated, spring-steel fasteners that replace threaded nuts, lock washers and spanner washers. On many applications they eliminate time-consuming assembly operations.

Fast and easy to apply, Speed Nut® Fasteners provide

maximum holding power at minimum cost per fastener. They don’t shake loose from vibration, yet can be easily loosened without worry about rust-frozen screw threads.

Industries and Applications

• Smaller components where space is premium

• Inside small electrical or mechanical components

Benefits

• Requires less torque than standard hex-nuts

• Can be installed prior to painting processes so threads won’t fill

Our Legacy – Our Future

The original flat-type Speed Nut® is still used today, but it has been replaced by self-retaining versions. Products like U-nuts and expansion nuts use the same technology and features that revolutionized assembly processes in the United States and throughout the world.

Nuts

Self-Locking Threaded Nuts

Most of the products featured on this page are manufactured with spring steel. ARaymond Tinnerman offers these parts in corrosion protection and/or aesthetically pleasing finishes. Parts may also be available in stainless steel.