Most of the products featured on this page are manufactured with spring steel. ARaymond Tinnerman offers these parts in corrosion protection and/or aesthetically pleasing finishes.

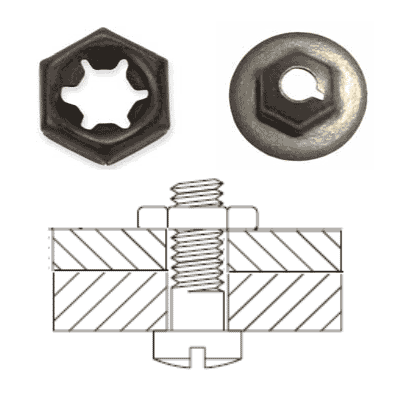

PALNUT® THREADED STAMPED NUTS

ARaymond Tinnerman Threaded Stamped Nuts are used in place of traditional hex-nuts for reduced weight or applications requiring lower torques. Parts are available in common screw sizes. The hex-shaped stamped nuts can be used in applications where screw length is restricted. They can also be used with a standard hex-nut to act as a jam nut.

Washer style nuts feature a stamped, integral washer. This allows the part to accomodate a larger hole without the use of a separate loose washer. Sealants can be applied to the washer to reduce moisture and noise intrusion.

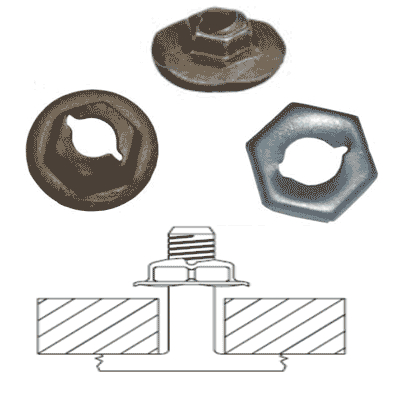

SELF-THREADING STAMPED NUTS

ARaymond Tinnerman Self-Threading Stamped Nuts have the same features as threaded stamped nuts, but form their own thread on a smooth die cast, mild steel, or plastic stud. The interference caused by the nut and stud creates a strong

locking force that prevents disassembly.

The hex-shape has the impression nearer to the base of the part. This can assist when stud height and assembly space is limited.

The washer type can accomodate a larger mating hole to compensate for component build variation. A seal can be added to the washer type nut to prevent noise and water intrusion.

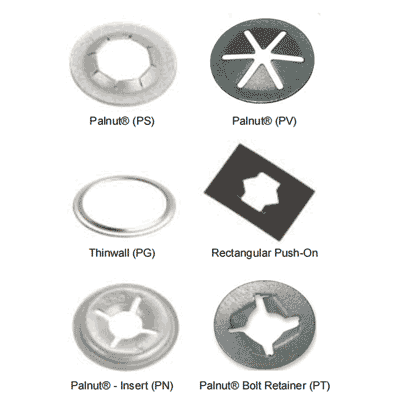

PUSH-ONS

ARaymond Tinnerman Palnut® Push-On fasteners provide a good balance between maximum holding strength and reasonable push- on force. They feature inner teeth that slide over and bite into a round stud, preventing two panels from disengaging. Push-Ons are applied much faster than standard hex-nuts.

PS and PV style push-ons are the most commonly used. The serrated teeth provide flexibility, allowing them to accommodate larger stud variations. The separation of the teeth add flexibility and reduce insertion efforts.

Thin wall fasteners are higher strength versions of the push-on family. The interior design is much more rigid, making them suited for higher retention applications. Rectangular removeable push-ons offer a different exterior footprint, and can be removed on a D-shaped stud by twisting the part 90 degrees. Inserts provide a larger bearing surface so parts can be installed with automated assembly or can be pre-assembled to trim pieces.

Palnut® Threaded Push-On Fasteners can also be used in assembly applications where screws or bolts need to be retained in place before a nut is positioned and tightened.

Industries and Applications

• Domestic Appliances

• Toys, lawn carts, and coolers with axles

• Small mechanical or electrical devices

Benefits

• Provides maximum holding power, eliminating warranty issues caused by vibration loosening

• No tools required – eliminating time-consuming assembly operations

• One-piece design eliminates the need for multiple small parts, reducing inventory space

• Low profile design, allowing parts to be used in small mechanical and electrical devices

Performance Specifications

Insertion and retention efforts are dependent on the material and material thickness of the part, the size of the spring fingers and the material of the stud. Retention capability is typically up to three times that of insertion efforts.

ARaymond Tinnerman will offer samples for testing or will perform testing on customer provided components.